Products

FRPP series

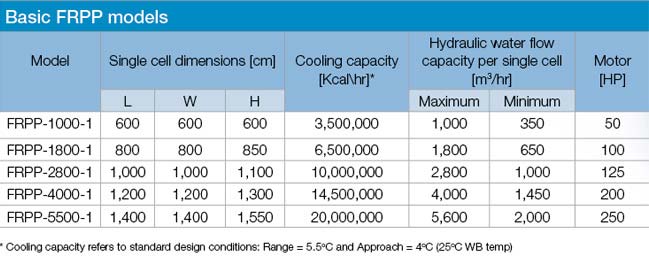

Pultruded FRP Counterflow Cooling Towers

General

YWCT’s FRPPs are induced-draft cooling towers made of FRP. The structure of our FRPP series (support beams and columns) is made of composite continuous fiberglass pultruded sections that comply with CTI’s STD 37 and conform to ASTM E84D with a flame spread rating of below 25. FRPP cooling towers are positioned over a concrete basin. Just as for our CING series, YWCT provides its customers with scale drawings of the concrete cement, including locations and production drawings of all pipe fittings in 2D or 3D. Also, as in our CING series, the size of a single cell ranges from 6m X 6m to 15m X 15m. When the concrete basin is ready on site, YWCT sends its assembly teams to the job site, where one team sets the pultruded FRP structure, and the other furnishes the cell once the first team has erected it.

Pultruded FRP cooling towers have become an alternative solution to traditional concrete cooling towers, since in many cases they cost less and their erection time is much shorter than that of cooling towers made entirely of concrete. In addition, pultruded FRP towers in many cases offer superior corrosion resistance.

Options

- Additional veil layers to increase corrosion resistance

- Pultruded FRP hand rails, walkways, and ladders

- Low-noise fans

- Complementary subsystems: filtration system, water treatment system, heat exchangers, VFD

- Nickel alloy connectors (e.g., Hastelloy C-22)

- Elevated basin for optimal use of space

Features

- Pultruded fiberglass polyester field – erected cooling towers

- Heavy – duty cooling towers designed for industrial applications

- Optimal thermal performance design Highly resistant to corrosive environments

Type

Counterflow

Fabrication

Field-assembled

Material

Pultruded and hand-laid FRP

Air Flow

Induced draft

Water Flow

400 - 4,000 m³/hr per cell

PRINT

PRINT