Case Studies

K. M. Sugar Mills, Ltd.

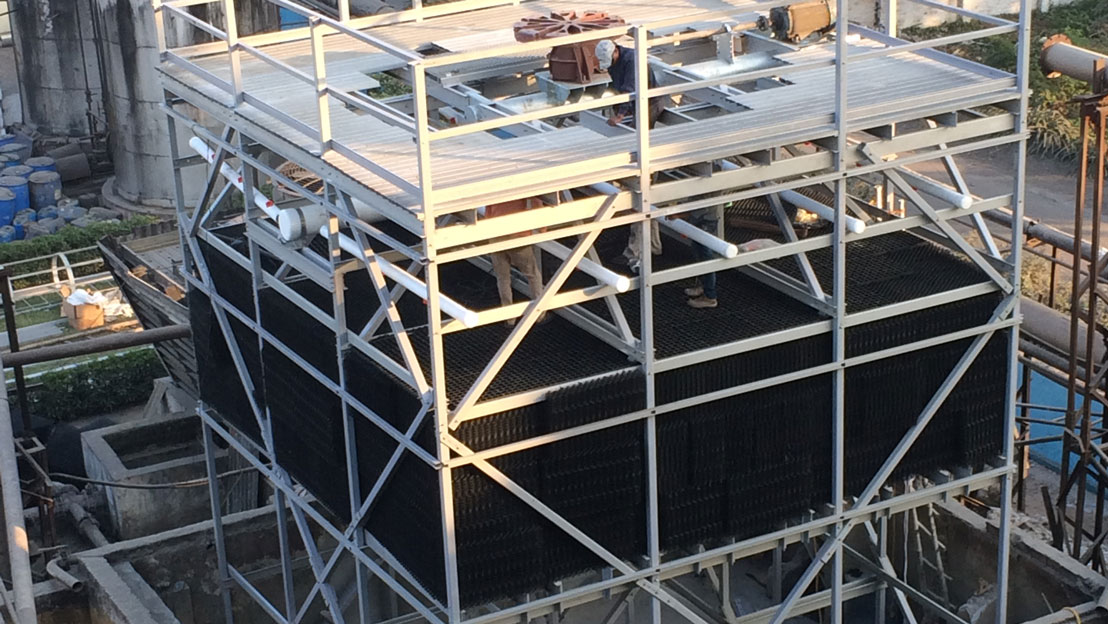

YWCT was asked to replace an old wooden cooling tower based on The cross-flow principle. We built a new, pultruded fiberglass tower based on The

counter-flow principle. The challenge was threefold:

- Harsh environmental conditions, including airborne sugarcane fibers

- Stringent design requirements (2 degrees’ leeway)

- The sugar harvest loomed, so that every of inactivity represented a loss of thousands of dollars.

YWCT designed a large-scale tower based on splash fill modules produced by Brentwood, whose cells fit the old cement pool precisely. Working

around the clock, our supervisor led the crews that erected the tower on site, completing the job successfully and on schedule

Year

2015

Construction

Pultruded FRP

Water flow

400 m³/hr

PRINT

PRINT