Products

CING series

Concrete Counterflow Cooling Towers

General

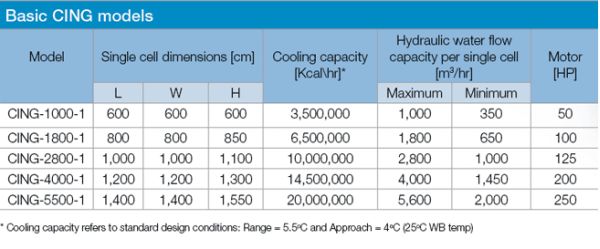

Concrete cement cooling towers designed for heavy industrial applications such as power plants; petrochemical and chemicals plants; and refineries of various kinds. YWCT provides its customers with scale drawings of the concrete cement structure, including locations and production drawings of all pipe fittings in 2D or 3D. The size of a single cell ranges from 6m x 6m to 15m x 15m.

In most cases, our customers (who are familiar with the local market and regulations) choose to take responsibility for the civil engineering and the concrete work. Our engineering department guides the concrete construction process from beginning to completion, ensuring that on-site work meets all requirements. While construction is taking place, all relevant parts of the cooling tower are purchased or manufactured and sent to the job site. When the structure is ready, our assembly team flies to the job site to install and furnish the cooling towers with fill, louvers, fan, motor unit, and fan stack until the cooling tower is operational. Operations are conducted by an experienced team of foremen and laborers, who can be assisted by local labor to reduce costs.

Choosing a concrete structure ensures the end user the longest product life for the cooling tower, and may be the least costly solution for certain customers who already work with a concrete contractor, particularly in locations where labor is less costly.

Options

- Polypropylene fill for high-temperature water

- Turbo-Splash fill for poor quality water

- Forced-draft appearance

- Low-noise fans

- Complementary subsystems: filtration system, water treatment system, heat exchangers, VFD

- Wooden infrastructure and insulated rubber

- Nickel alloy connectors (e.g., Hastelloy C-22)

- Atmospheric distribution system

- Elevated basin for optimal use of space

Features

- Concrete cement counterflow cooling towers

- Longest service life in harsh environment

- Erected on site

- Pultruded FRP fill support

Type

Counterflow

Fabrication

Field-assembled

Material

Concrete cement

Air Flow

Induced draft

Water Flow

400 - 4,000 m³/hr per cell

PRINT

PRINT