Case Studies

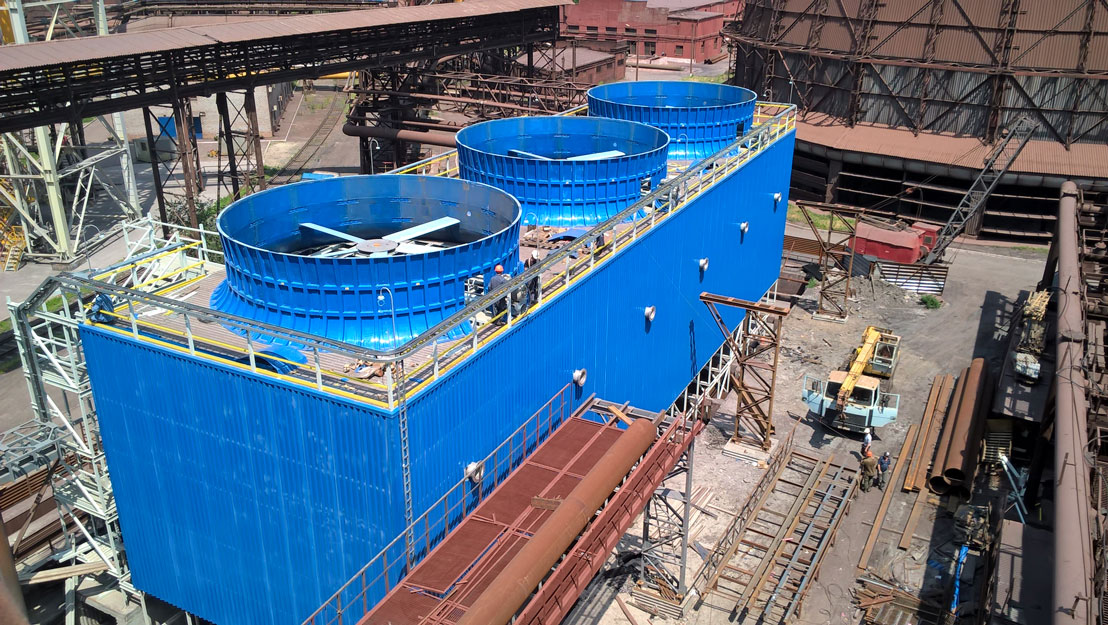

Zaporizhye Steel II, Ukraine

YWCT was asked to replace an old cooling tower that was operating

under extremely harsh conditions in a steel mill in the Ukraine.

Circulating water inlet temperature was 65o C., and it was expected

to exit the cooling tower at 35oC.

In order to stand up to the harsh conditions, YWCT designed a high

induced-draft counterflow cooling tower with no fill at all.

The distribution system was designed as an array of open channels that

enable cleaning easily.

Distribution was based on special no-clog pigtail nozzles.

The nozzles were installed at the outlet of 2m pipes to ensure the

correct pressure/head and optimal distribution.

The nozzles, channels, and pipes were all made of 316SS-grade

stainless steel.

The cooling tower was completed in less than two months.

Year

2016

Construction

Pultruded FRP

Water flow

4,000 m³/hr

PRINT

PRINT