Case Studies

Pizzarotti and Shapir Engineering

The joint venture of Shapir Engineering and Impresa Pizzarotti & C. S.p was awarded the contract to excavate the 11,000m long tunnels for the train to Jerusalem.

The required temperature for the drilling machine was below the summer wet bulb temperature in the area.

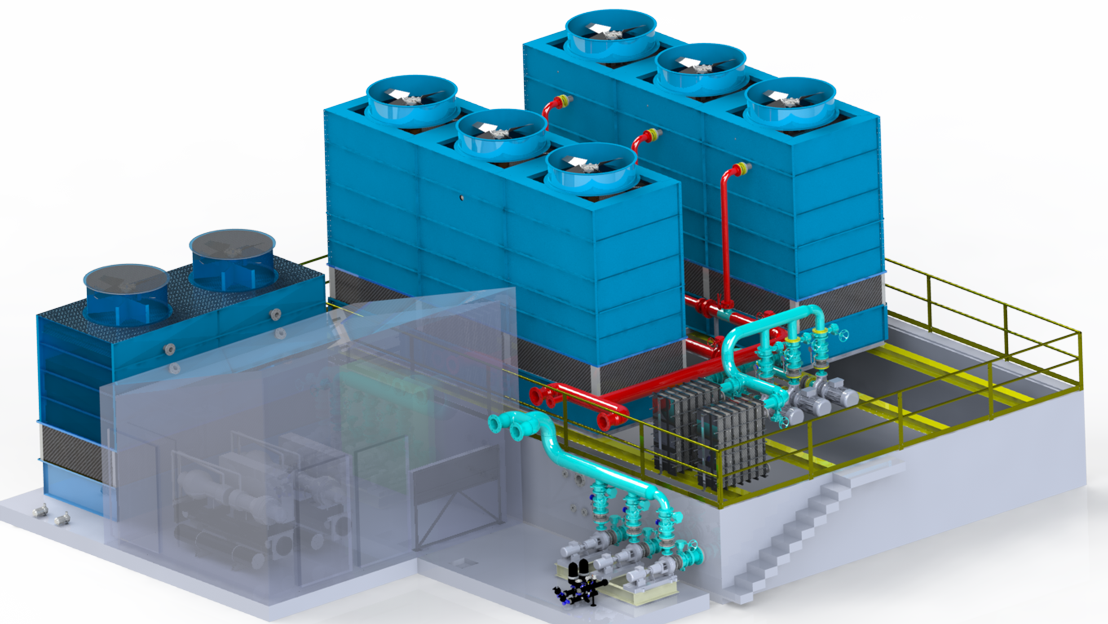

YWCT designed and built a cooling system that enabled wintertime cooling based solely on cooling towers.

During hot summer days, cooling is divided into two phases: First, water is cooled by cooling towers as close as possible to the wet bulb temperature, then cooled to a lower temperature using chillers.

The project was delivered in turnkey mode and included cooling HDG cooling towers over a concrete basin, chillers, pumps, electric and control panels, and heat exchangers.

The efficient solution saved the joint venture money on initial investment in equipment and reduced the ongoing operational expenditures significantly.

Year

2012

Construction

HDG

Water flow

450 m³/hr

PRINT

PRINT